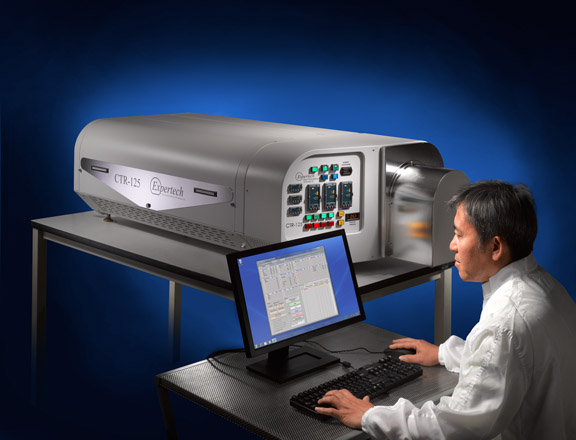

Diffusion / LPCVD Furnace Systems

The smaller footprint, small batch furnace solution.

- Production style performance in a small footprint

- Fully automated, recipe driven processing

- Ideal for pilot lines and development labs

- Small space saving footprint – and stackable

The CTR provides an exceptionally small footprint system and is stackable. Providing both atmospheric pressure and LPCVD processes, the CTR is an ideal solution for pilot lines, R&D labs, and government and university laboratories.

Model CTR-125 – processes substrates up to 125mm diameter.

Model CTR-200 – extends the processing range to 200mm diameter substrates. (Processes 125mm and 156mm square substrates, too).

This system has capability far beyond the tabletop or laboratory diffusion furnaces of the past. Fully automated and recipe driven the results rival the uniformity and film quality of full size production systems.

CTR benefits:

- Compact design enables more efficient utilization of high cost clean room space.

- Stackable – up to four for the CTR-125 or three for CTR-200 systems fit in the same compact footprint.

- Safety interlocks, both hardware and software complying to industry standards.

- Recipe execution – recipe control, storage and data capture using a PC-computer based control system.

- Cantilever automation, controlled rate of load insertion and withdrawal using the optional Expertech autoloader.

- Savings on facilities cost – using compact water cooled heater element.

- A wide range of atmospheric and LPCVD processes available.